Compared to other two weeks, this week was the

most successful one. I was able to freely express my ideas and

successfully create the things that I wanted. The prototypes clearly showed the

design flaws that I can change to make a better project, and meanwhile I

learned several different functions of Fusion 360 that can be used

appropriately. I also created small and simple projects for the students in

Proctor for their personal use or classes. All these activities were

satisfying. I was relieved that I had physically printed models that can be

shown for the presentation that shows my effort. Of course, not everything went

very successfully as anything else. Every project was changed at least five

times and each of them required a major change in multiple aspects. When I am

pondering on how I should change my project, it may seem like I am doing

absolutely nothing, but I actually simulate the changes numerous times before I

make a change in the project to seek for the best possible outcome. On the

other hand, I still wasn’t completely satisfied with the final products because

of the design. Currently, all I can do is filleting the edges to look rounder

and more refined. When I see other models online that has been downloaded multiple

times, I can see why their projects are so popular. The overall quality exceeds

that of my projects, but such thing cannot be overcome simply by looking at

others’ designs. At the end, I felt achieved on printing out the three versions

of phone stands and two versions of the battery box. Whether people would

download it or not, I believe they can be used usefully to people.

Tuesday, May 24, 2016

Monday, May 23, 2016

May 20th

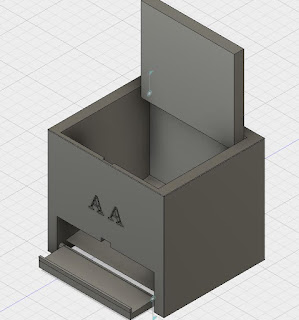

Since I finished the triple A battery box, I copied the file to create a double A battery dispenser. I widened the box and also modified the lids.

The rest of the day was spent printing out the iphone 6 plus and iphone 6 version of the phone stand. The charger hole was too small for the chargers to pass through, so I had to expand the bottom surface and the hole. I also enlarged the stand to stabilize it.

The rest of the day was spent watching the projects being printed out to see if there is any problem with the print.

May 19th

After modifying the phone stand, I chose to create a better version of the battery dispenser. The prototype was terrible. The hinges were too weak and wasn't printed the way I wanted. This included both the design flaw and 3D printer problem. Now that the tech center have a better filament and I have enough time to work on the next project, I chose to work on the older projects to finalize them. I increased the radius of the cylinders that were holding the lid. I also had to make the lids smaller so that the printer doesn't recognize it as the same body as the box itself. The second model's problem was that the top lid created too much supports inside that I couldn't get rid of all the supports, and it was too dirty inside. Thus, I rotated the top lid by 90 degrees. The result was satisfying. Everything worked the way I wanted.

May 18th

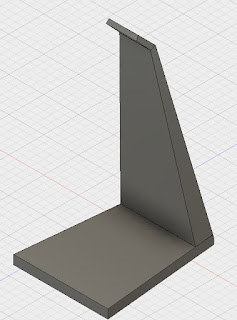

Designing the stand was relatively easier. It just had to be stable enough to withstand the weight of the phone. However, modelling was harder than I thought. I had to sketch each sides and pull those surfaces out to construct the entire model one by one. The problem was that in order to create a stand that gets constantly narrower, I can't just pull out from one sketch because I couldn't adjust the points of the extruded model. I looked at the modify tools of Fusion and learned how to use draft for this model. Draft solved this issue easily. All I had to do is choose the surface that is contacting the surface that I wanted to adjust, then choose the surface that I want to tilt. This way, I created a sketch sideways, pulled out the model from the sketch and narrowed the surface from back to front easily. However, the prototype didn't fit because I chose the exact size of the hole that was mentioned in the holder. Thus, I decreased the contacting side.

May 17th

The prototype had couple problems. The phone didn't fit the holder because I used the exact dimensions from the website. I didn't consider the expansion in filaments and small error among the dimensions. I enlarged the holder and the slot that contacts with the stand. Since the slot was too small and long, I was worried the contacting surface would break easily and won't be stable enough. Also, I filleted the surround arms because the phone's bottom surface is round and sharp edges from the holder can damage the phone. Round surfaces looked much better the sharp edges. I printed out the new model and everything fit perfectly.

May 16th

The motivation for the new project came from using the phone in the bed. Since I had to hold my phone above my head while lying down on the bed, my arms hurt from doing so. At first I wanted to create a phone bed stand, but soon realized that it is easier to make a regular phone stand first, then think about making one that also works for the bed. As the thoughts proceeded, I chose to make a design that can be rotated without using a particular mechanism. I also wanted a stand that is simple and effective. The idea was to make a stand that holds the phone and stand at the same time. However, if it can be rotated sideways, the stand and phone holder has to be separated. The result was  .

.

The phone holder can hold the phone and has a slot at the back so that it can be connected with the stand separately. In the afternoon, I printed out the prototype to see if there is any design flaw.

.

.The phone holder can hold the phone and has a slot at the back so that it can be connected with the stand separately. In the afternoon, I printed out the prototype to see if there is any design flaw.

Thursday, May 19, 2016

Weekly Reflection 2

As soon as I

changed my thoughts in my potential 3D-printing projects, my life has been

simpler in reaching the objective. I was able to create plans for useful things

such as wire organizer, phone stand and battery box. Coming up with the idea of

making these objects was easy because they already exist in the internet that I

didn't come up with a completely new idea. However, making these were difficult

because even though I had a great idea in making these objects before modeling,

sometimes it didn't work out at all and sometimes it was out of my ability to

finalize the project. Normally it would take multiple hours of fixes in the

model for me to realize that I cannot proceed, so some of the projects like

switch key. These projects took up about half of the time. On the other hand, I

have battery box and wire organizer that was successful after going through

multiple versions. Overall process was enjoyable and I learned multiple

lessons. I learned why there are designers and engineers in the company and why

engineers always have to take some design class in college. Also, the project

cannot be finalized in one step. It normally requires numerous changes and

dedication to produce a solid result. After all, I definitely achieved more

than last year.

Wednesday, May 18, 2016

May 13th

Finally finished the model for the triple A battery box. In the morning, I came to the tech center and worked on the top lid of the box that can prevent the battery from falling out when the box had to be carried around.

Since Jim Cox, the genius tech center director, fixed the 3D printer filament jam issue by putting the filament roll somewhere else than attaching it to the printer, I decided to print out the model that is shown above. I had to observe the print for couple hours as the two components, including the bottom and top closing, might not be printed out perfectly due to the design issue. Few hours later, I figured out that the such model wasn't printing out well because the closings were attached to the box than freely moving. I canceled the build and tried to troubleshoot the issue. Moreover, I had to think about a new design I wanted to work on.

Monday, May 16, 2016

May 12th

My entire day was spent on creating the model of the triple A battery stacking box. Yesterday, the mouse in the tech center ran out of battery, so I asked tech center for more batteries to use for the mouse. All the batteries were stored in multiple packages inside the small drawer. After seeing this, I chose to make a container for the batteries that can be stored and obtained more easily. The modeling wasn't as hard as I thought, but coming up with the way to get the battery from the closed box. Since this box doesn't involve any other materials like springs, and I wanted to open the box manually, I had to use the simplest design for 3D printing. The end result was

Thursday, May 12, 2016

May 11th

In the morning from 9:30a.m. to 12p.m., I spent my time searching other people's wire organizer to get the idea of what others created for their own use. Most of them were supported by the double-sided tape, which can be simply accomplished without a mechanism or magnets. The rest of the day was designing, calculating, and modeling the wire organizer for the table edge. Since I had problem creating the appropriate hole along the perpendicular surfaces, I had to look up the tutorials of some tools for Fusion 360. The project is not perfect, but hopefully can be refined at the end of the senior project.

May 10th

After waking up at 9:30 a.m., my first job was to create the model for the proctor logo. Since none of my goals were achieved, I decided to create a simple logo that can be used as an ornament in the tech center for the visitors. I came down to the tech center at 12:30p.m. since the last printer that was being used by the engineering class was done with their print and can be used. Unfortunately, it showed me a filament jam error that I chose to go to lunch. I came back to my room and realized that I don't have to create a complicated model like the switchkey that is probably not very useful to everyone. As I browsed earlier, I wanted to create something that is simple and useful like the proctor logo I made.

May 9th

Due to the inactivity of the printers, I chose to do something else than trying to print out the prototypes. I browed websites to see other people's projects that can help our everyday life. I tried to work on the model of the prototype, but I couldn't proceed. Most of the days were spent surfing on the internet for new ideas.

Monday, May 9, 2016

Weekly reflection

Nothing went perfectly as

I expected. My plan was to spend my entire time come up with ideas for the

model projects, design and model the project, and print the project. Although I

thought I could create one project quickly, one project took more than

one-third of the Senior project duration. This occurred due to three printer

malfunction, which made my sponsor and the owner of the printers Jim order me

to fix the printer since I was the only one who had enough time to spend on the

printers. Thus, I spent more than half of the working hours during the week,

but still couldn't fix it. This wasn't actually included in my objectives, so I

am worried what I should present later on the last week of school. The trouble

shooting process was more frustrated than what I expected because of numerous solutions

and vague explanations on the issue. Since all I know is that the print is

skipping in x-axis, there can be many possible issues and solutions for the

printer. Some threads were saying that such printer had this chronic problem

that was never actually fixed as the company released the "solution".

I hope the last printer that was being used by others does function well.

Modeling was fun compared to the unexpected issues on the printers,

however. I was able to express my ideas to create what I wanted. Hopefully this

week I can print out my project.

May 7th

Since I didn't go to the tech center today, I mostly worked on the ideas and the model that I created. From 9:00 a.m. to 12:00p.m., I spent my time looking at what others created on the internet. People made something very useful, such as self-watering planter, or very aesthetic, such as a Colosseum model. I tried to figure out what I should make to aid my life and others in the school. 1:00p.m. to 3:30 p.m. was mostly spent on actual modeling, but it was hard to make a progress because I needed a physical model to be referenced for the measurements and details.

May 6th

For the entire 5 hours of the day, 10a.m. to 3:30 p.m. excluding the lunch time, was spent on the maintenance for the printers again. I tried to print out the prototype of my project in order to figure out the physical schematics of what I created, but I couldn't print on the three printers due to filament jam and skipping. The last printer was being used by someone else. I disassembled the smart extruder to figure out the problem, but it created more issues.

Friday, May 6, 2016

May 5th

Today's job was the prolonged version of yesterday's work. The 3D printer I tried to fix yesterday turned out wasn't fixed after the small print. Since the extruder was moving extremely fast and the print was slipping constantly, I thought adjusting the print speed would fix it. Then, I tried to fix the cables for the x-axis endstop. Well none of these worked. I had to read several articles to adjust it in the morning, but couldn't figure out the right solution. The fix will be paused until I finish my current project, or hopefully my great, more experienced advisor Jim would figure out the solution.

Thursday, May 5, 2016

May the 4th

It was a great morning to start off with

this on my sight at 10 a.m. Yesterday, I started a print due to my sponsor, advisor, tech director, and the owner of the 3d printers Jim's request so that he can display great 3d printer products to the visitors and students. Today, I figured out that the printer wasn't working well and I have to fix two printers. I spent my entire morning watching videos to fix the issue such as clogged extruder. The short moment in the afternoon, which as 6:00 p.m.~7:30 p.m. was spent to improve the project that I was working on.

this on my sight at 10 a.m. Yesterday, I started a print due to my sponsor, advisor, tech director, and the owner of the 3d printers Jim's request so that he can display great 3d printer products to the visitors and students. Today, I figured out that the printer wasn't working well and I have to fix two printers. I spent my entire morning watching videos to fix the issue such as clogged extruder. The short moment in the afternoon, which as 6:00 p.m.~7:30 p.m. was spent to improve the project that I was working on.

Tuesday, May 3, 2016

May 3rd

Although I created a design and the mechanism, today I realized that it wouldn't work. Therefore, I had to come up with the new design starting at 9:00 a.m. I watched several different mechanisms to reference it for the one that I was making, and this continued until lunch. After lunch, I finalized the new design for the project and started working on the model for Fusion 360 until 3:30 p.m. Hopefully I can finish modeling tomorrow.

May 2nd

As the first day of Senior Project went by, I realized how hard starting my own project can be. Starting from 9a.m., I had to come up with the design for the project I wanted to work on for the next few days. The very first project I decided to work on is a switchkey: a key that utilizes the switchblade mechanism. I believe it would be more comfortable for the students to carry the keys around. After lunch, I continued working on the design and also helped a student who was trying to print out his engineering class project. I started on modeling at 2:30p.m. and stopped working for the day at 3:00p.m.

Subscribe to:

Posts (Atom)